If you need it, we can provide it. Send us your requests and our customer service team will quickly get you an answer.

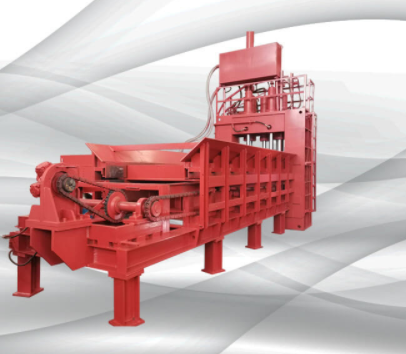

Request a QuoteScrap metal shears are mainly used for cutting metal materials, and are suitable for cutting various recycled scrap metals according to length into raw materials for de novo smelting. The shearing force is large, the size format of the cutable material has a wide practical range, and the cutting can be continued. The correct operation of scrap metal shears can effectively increase the life of the equipment and at the same time increase the production efficiency. Next, our scrap metal shears suppliers will introduce to you the safe operating procedures for scrap metal shears.

1. Before use, carefully check whether all parts are normal and whether the fasteners are firm. Check that the oil in the oil storage tank of the shearing machine should be sufficient. After starting the oil pump, check the valves and pipelines for leakage. The pressure should meet the requirements. Open the air release valve to release the air in the system.

2. It is forbidden to cut unannealed steel parts, soft metal parts, cast iron parts, over-thin work pieces less than 100 mm in length, and work pieces that exceed the length of the scissors.

3. Scrap metal shearing equipment should be operated by a person, and other people are not allowed to use it without training.

4. During operation, the human body is not allowed to approach the transmission part and the knife edge of the equipment, and attention should be paid to the safety of the surrounding personnel to prevent the material from lifting up and hurting people. When cutting, the material should be cut as close as possible to the inside of the knife. When cutting short materials, it is strictly forbidden to use hand-held work pieces to feed, and clamps should be used for feeding.

5. When the scrap metal shearing machine is in operation, the operator is not allowed to leave the post without authorization, and the power supply should be cut off immediately after the work is completed or temporarily.

The scrap metal shear has a large shear force, and the size format of the cutable data is wide and practical. It can continue cutting and has high production efficiency. When the high degree of scrap metal does not move, the oil pump can actively reduce the flow, and the motor will not be overloaded. Burn out, so the reliability of the machine is high, and the application life is long. It is an important partner for the metal material recycling department to cut waste. Scrap metal shears are very versatile, suitable for the calibration of shaft parts and profiles, the pressing of shaft sets, the bending of plates, the embossing, stretching, and the suppression of plastics and powder products.

Irregular use of scrap metal shears can easily cause injuries. Our scrap metal shears suppliers specifically introduces you to the safety operation precautions of scrap metal shears for this safety issue, and hope to help you. If you need to buy scrap metal scissors, you can contact us and we will do our best to help you.

By continuing to use the site you agree to our privacy policy Terms and Conditions.