If you need it, we can provide it. Send us your requests and our customer service team will quickly get you an answer.

Request a QuoteWaste recycling equipment is becoming more and more intelligent. The concept behind scrap metal recycling is simple: there are still many valuable parts in the scrap, which can be resold to buyers for new products after being effectively recycled. Therefore, the waste that seems to belong to the landfill actually still has a lot of practicality and practicability.

Nowadays, scrap metal recycling is being vigorously promoted because recyclers can provide quality products to buyers. One of their ways to achieve this goal is through the use of SBL in recycling.

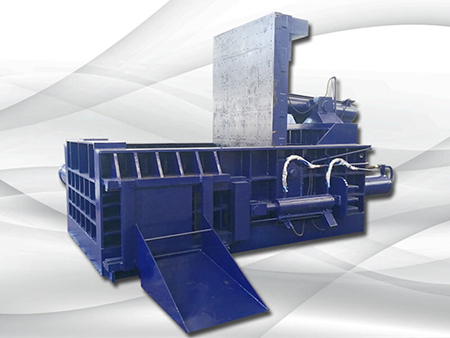

SBLs, which stands for shear/baler/loggers, are a type of heavy machinery specially designed to provide scrap recyclers with multi-functional equipment for processing heavy and light metals.

In this way, logs, bales or cut-to-length materials are produced for buyers to use. It demonstrates the efficiency of bringing scrap metal baler to a recycling station and explains why recycling is always a better option than taking scrap to a dump.

What is SBL and how does it help recycling?

The scrap metal recycling industry will provide first-class products by using first-class equipment. SBL is a good example.

SBL conveys non-ferrous or non-ferrous metals. It will be reduced to a suitable size to be compressed into a log, and then cut to a certain length by shearing, or compressed into a denser bale.

Logs, bales or cut-to-length materials are discharged and ready for transportation. Today, SBL equipment is automated, mobile and efficient. This also reminds us that the waste recycling industry is constantly innovating.

The latest shears/balers/recorders provide scrap metal recyclers with multiple functions for processing metal materials.

The SBL model can be fixed, portable or mobile. They are made of high-strength steel structure and are carefully designed to function under extreme conditions.

More importantly, today's SBL uses complex software, electronic equipment and hydraulic systems. Some use remote control operations to provide enhanced security and machine monitoring capabilities. Maintenance is also simplified.

Portable and mobile devices are easy to load on a trailer for transportation, and can be quickly set up without a base. Both portable and mobile SBLs are universal because they can effectively handle heavy iron and non-ferrous light metals.

Portable SBLs are becoming more and more popular, and due to the financial savings they provide, this number is expected to grow.

SBL can be driven by diesel engine or electric, and is designed as a stand-alone type. Shears/balers/recorders can provide the versatility of three machines in one device, depending on the tonnage of scrap obtained by the recycler and the cutting force required for the material.

Why is this important?

In today's highly competitive global market, recycling facilities need to prepare materials and be ready to quickly ship them to the market. SBL is able to produce the correct tonnage required for production to help you.

The ever-changing market means that scrap recyclers need multi-functional waste processing equipment so that they can quickly adapt to market changes. But it's not just efficiency.

Advanced equipment can make waste recycling stations operate more efficiently and provide buyers with high-quality products. The benefits it brings far exceed the company's bottom line.

The more successful the recyclers deal with waste, the more likely they are to show why recycling is important to everyone.

Recycled metals have strong economic benefits. The industry has created thousands of jobs and brought tax revenue back to the state and local economy. They also help reduce the cost of manufacturing new products.

Compared with mining raw ore to produce new metal, the cost of recycling metal is much lower. Mining is a much more expensive proposal. It also consumes more energy and places a greater burden on our natural resources.

On the other hand, recycling metals is more energy efficient and will not harm our water or the land where mining is conducted. But this is not just about the economic incentives for recycling.

How does recycling help our environment?

Recycling is a way to help keep the environment clean. It's that simple.

Scrap metal contains toxic chemicals such as mercury and lead. If the waste is transported to the dump and left in the dump, these toxins will seep into the soil and pose a risk of pollution to nearby land and water.

On the other hand, recycling waste can eliminate this risk. Instead, the metal is processed by an experienced team and then made into metal that can be used in new manufacturing. The environmental threat has disappeared.

This is the key reason why investment in new technologies in the recycling industry is so important. Every step in the process of making new metals helps to prove that if we treat waste as garbage, waste recycling not only solves a series of environmental challenges, but also makes for a stronger investment in recycling technology. Argument.

In conclusion

Nowadays, researchers and companies specializing in recycling are looking for innovative ways to make the process of separating metals and their individual components more efficient and cost-effective.

These innovations provide the possibility to significantly increase the recycling rate, which is a major contribution to our environment. For more information, please call +86-15896496066 to request the latest quotation.

By continuing to use the site you agree to our privacy policy Terms and Conditions.