If you need it, we can provide it. Send us your requests and our customer service team will quickly get you an answer.

Request a QuoteAs the need for reduction in environmental pollution increases, different companies devise a number of ways to handle scraps. For instance, scrap metal balers are used to crush and cut different scraps into different shapes.

Investing in a quality scrap metal baler from a reliable and experienced manufacturer in the industry is the best way to get the best experience. Moreover, you are sure to get a quality machine that meets your needs.

Read on as we take you through important things you need to know about this well-designed machine.

The operation of this machine is through the adoption of hydraulic transmission to carry out the baling process. There is a sealing element that has a high resistance to high temperature and pressure.

The materials are fed into the press box. The high-pressure oil is compressed to enter the back cavity of the cylinder top. This causes the piston to reach out and touch the articulated cover of the press box.

The high-pressure oil enters the main cylinder through the back cavity. This causes the piston rod to reach out and drive the main pusher to the front of the metal box.

The process continues as the machine compresses the metal scrap into bales of different shapes and sizes. It is very useful in handling and recycling metal scraps from different industries.

There are two major types of balers. They are:

· Horizontal balers

· Vertical balers

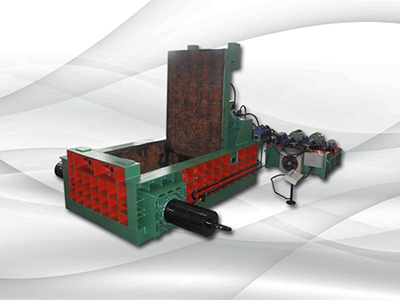

Horizontal balers use the working approach of side-to-side operation of the hydraulic press. There is the full automation of the operation. Due to this, very few or no personnel operate the machine.

The conveyor belt loads the machine at an improved speed. This increases efficiency and productivity. Most time, this scrap baler is used when wastes are large.

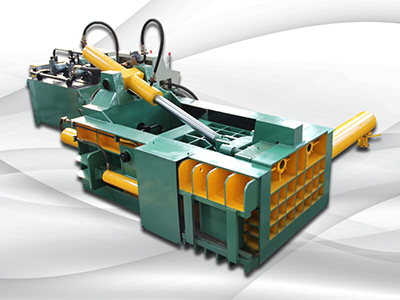

Vertical balers use the working approach of up-and-down operation of the hydraulic pressure. The vertical baler is fairly inexpensive compared to horizontal balers. It is not fully automated.

The machine requires an operator that loads and unloads the process. It is suitable for small businesses because it can process a small number of metal scraps.

The following are benefits of using this machine:

1. Easy recycling of metal wastes

2. It reduces the operational costs of the company by reducing the amount of money used for new resources.

3. It makes the creation of new components from recycled metals easy and affordable.

4. The machine is suitable for a wide range of metal scraps such as auto parts, machinery parts, aluminum scraps, electronic appliances, and iron pipes.

5. Brings more revenue to the company through recycling and reuse of scrap components.

Applications Of This Machine

The machine is powerful enough for different industrial uses. Some of the applications are

1. Dismantling of car scraps

2. Smelting of metals

3. Recycling of metal wastes

4. Recycling of industrial wastes

Invest in a quality machine from our company. As a reputable and experienced manufacturer, we produce quality machines that meet the needs of our clients.

Kindly contact us for a quality machine for your company. We are determined to provide the best services to you. Click here to check our products.

By continuing to use the site you agree to our privacy policy Terms and Conditions.