If you need it, we can provide it. Send us your requests and our customer service team will quickly get you an answer.

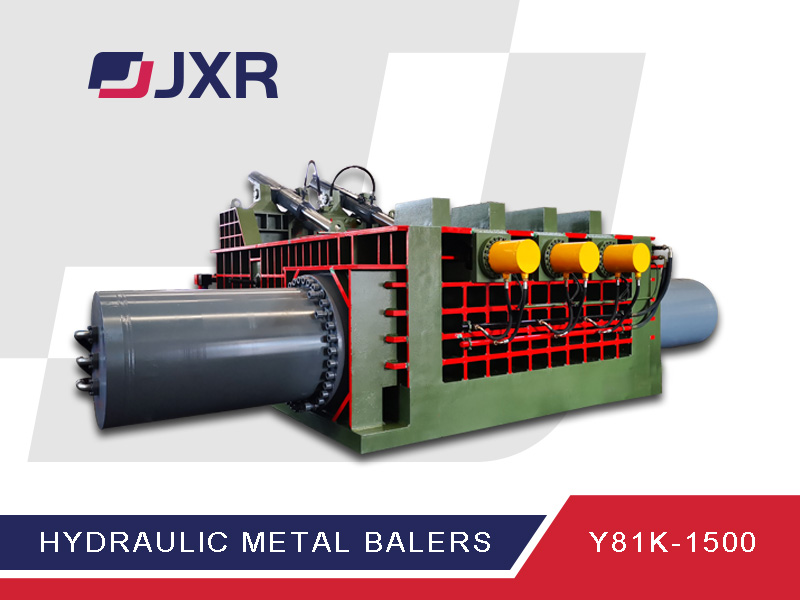

Request a QuoteThe hydraulic packaging machine can press various metal scraps (such as steel shavings, scrap steel, scrap aluminum, scrap copper, scrap stainless steel, and scrap automotive waste) into qualified furnace materials in various shapes such as rectangular, octagonal, and cylindrical shapes, which can reduce transportation and smelting costs and improve furnace feeding speed.

This series of packaging machines is mainly suitable for steel mills, recycling and processing industries, as well as non ferrous and ferrous metal smelting industries.

All metal baling machines models are hydraulically driven, with the option of manual or PLC automatic control operation;

There are different ways of discharging materials, such as flipping the package, pushing the package (side push and forward push), or manually picking up the package;

Installation require foot screws, and diesel engines can be used as power in areas without power supply;

There are ten levels of press pressure from 63 tons to 2000 tons for users to choose from, with production efficiency ranging from 1 ton per hour to 40 tons per hour.

The size of the compression chamber and package block can be customized according to customer requirements.

High speed, high efficiency, and low energy consumption. Improve the work efficiency of hydraulic presses and reduce production costs.

Mechatronics and hydraulics integration. Fully and reasonably utilize advanced mechanical and electronic technologies to promote the improvement of the entire hydraulic system.

Automation and intelligence. The rapid development of microelectronics technology has provided sufficient conditions for the automation and intelligence of hydraulic presses. Automation is not only reflected in processing, but should be able to achieve automatic diagnosis and adjustment of the system, with the function of fault preprocessing.

Integration and standardization of hydraulic components. The integrated hydraulic system reduces pipeline connections, effectively preventing leakage and pollution. Standardized components bring convenience to machine maintenance.

By continuing to use the site you agree to our privacy policy Terms and Conditions.